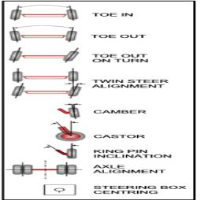

Wheel Alignment Procedure

Wheel Alignment ProcedureSTEP 1. A Steertrak Engineer will approach each vehicle with an open mind and will give consideration to any information given by the operator regarding load, tyre type and condition, and vehicle handling characteristics. STEP 2. The self centring frame gauges are carefully located on the chassis and then wheel rim run-out compensation is undertaken to accurately determine the measurement reference points. STEP 3. Worn or damaged mechanical components can cause tyre wear or impact the vehicles handling. Wherever possible the engineer will attempt to identify if any components are damaged or worn, and will recommend replacement or repair prior to adjusting the steering/axle geometry. Possible issues could be incorrect tyre pressures, track rod condition, worn ball joints, worn wheel bearings, worn steering gear, damaged suspensions, worn or seized king pins and possible chassis issues. STEP 4. Undertake laser measurements of appropriate parameters and check steering box timing. Calculate readings and compare with specification. See sample report sheet.... STEP 5. Make appropriate adjustments to the steering box timing, steering wheel alignment, track rod ends, drag links, etc., and repeat measurements. STEP 6. Take final readings and complete technical report.Visit the Steertrak (UK) Ltd website for more information on Wheel Alignment Procedure