Why Checking Surface Compatibility is Crucial When Overcoating

When it comes to rustproofing and automotive restoration, applying a high-quality coating is only part of the process. One often overlooked but essential factor is surface compatibility. Ensuring that your new coating adheres correctly to the existing substrate can make the difference between long-lasting protection and premature failure. At Rustbuster, we stress the importance of checking surface compatibility before overcoating to achieve the best possible results.

Understanding Surface Compatibility

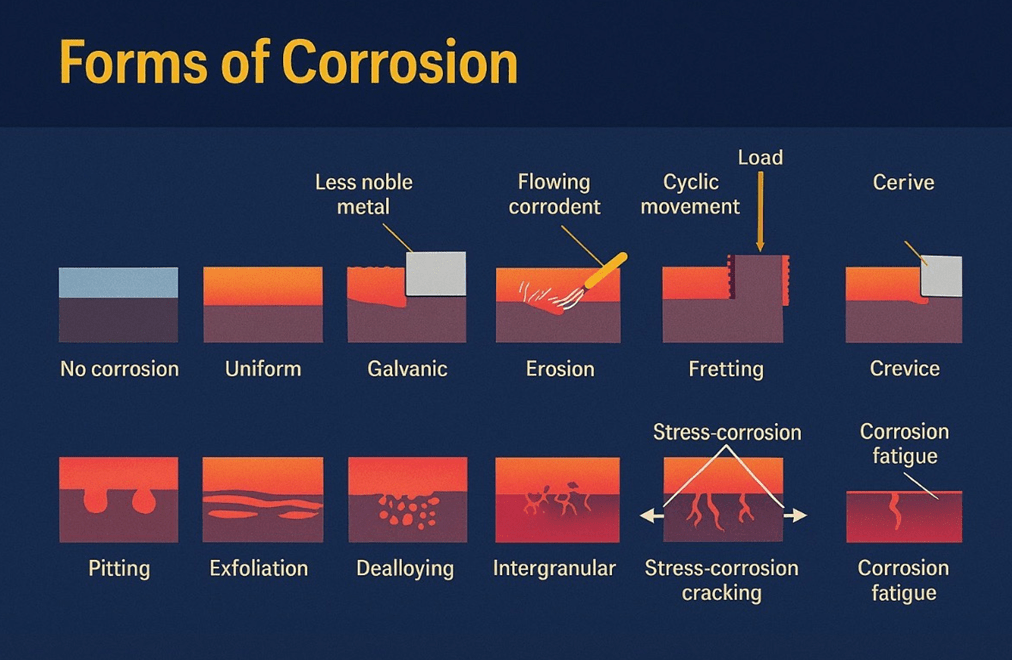

Surface compatibility refers to how well a new coating bonds with the existing surface or previously applied layers such as paint, primer, or rustproofing treatments. Different coatings have different chemical compositions, and not all are designed to work together. Applying a product that isn’t compatible can result in poor adhesion, peeling, blistering, or even accelerated corrosion.

For example, our Rustbuster Armaguard Epoxy Mastic is formulated to adhere exceptionally well to bare metal and lightly rusted surfaces, but proper surface preparation is required for it to bond successfully to existing coatings. Without checking compatibility, a topcoat may fail to adhere, leading to cracks, water ingress, and compromised rust protection.

Skipping this crucial check can result in several issues:

1. Poor Adhesion

If the new coating doesn’t bond properly to the substrate, it will eventually begin to peel. This is especially problematic in vehicle restoration, where exposure to moisture and road salt can rapidly accelerate deterioration.

2. Chemical Reactions

Some coatings contain solvents that may react with the existing layer, leading to softening, wrinkling, or complete failure of the base layer.

3. Inconsistent Finish

Incompatibility can cause patchy or uneven coverage, which not only looks unprofessional but may compromise the coating’s performance. This is particularly important for classic car restorations where appearance is just as vital as durability.

4. Wasted Time and Money

If a coating system fails, the surface will need to be stripped and redone—costing you time, effort and money that could have been avoided.

How to Ensure Compatibility Before Overcoating

Check Manufacturer Guidelines

Always consult the technical datasheets of both the current and new products. At Rustbuster, our product information is designed to help users make informed decisions on surface preparation and product compatibility.

Carry Out a Test Patch

Apply the new coating to a small, inconspicuous area and allow it to cure fully. Look for signs of poor adhesion, bubbling, or wrinkling before proceeding with full application.

Prepare the Surface Correctly

Surface prep is crucial. This could include degreasing, sanding, or applying a primer like Rustbuster’s Techshield Isolating Primer. For example, when overcoating Rustbuster 421 Epoxy, lightly abrading the surface will help improve adhesion.

Stick to Compatible Systems

Wherever possible, use products from the same manufacturer. Rustbuster coatings are designed to work together as a system, reducing the risk of incompatibility and improving performance and longevity.

Conclusion

Checking surface compatibility before overcoating is a vital step in any restoration or rustproofing project. It helps ensure proper adhesion, avoids unwanted reactions, and guarantees a durable and professional finish. At Rustbuster, we’re committed to delivering high-performance coatings backed by expert guidance, so your restoration work stands the test of time.

Before applying your next coat, take a moment to confirm compatibility—your vehicle’s protection and performance depend on it.

Visit the Rustbuster Ltd website for more information on Why Checking Surface Compatibility is Crucial When Overcoating